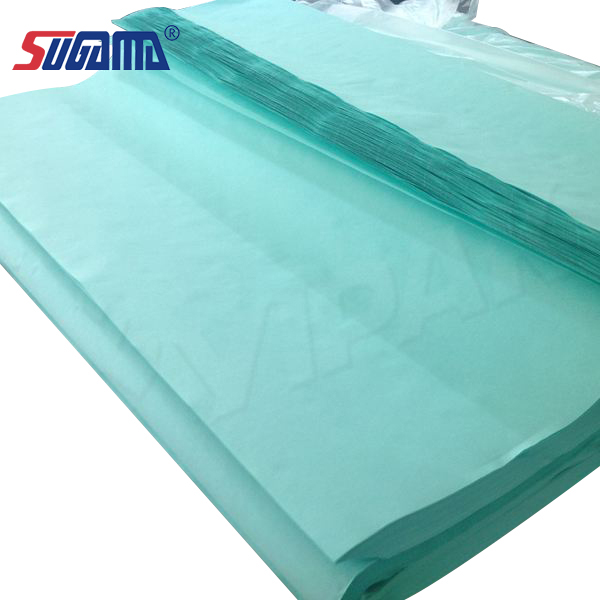

SMS Sterilization Crepe Wrapping Paper Sterile Surgical Wraps Sterilization Wrap For Dentistry Medical Crepe Paper

Size & Packing

|

Item |

Size |

Packing |

Carton size |

|

Crepe paper |

100x100cm |

250pcs/ctn | 103x39x12cm |

| 120x120cm | 200pcs/ctn |

123x45x14cm |

|

|

120x180cm |

200pcs/ctn | 123x92x16cm | |

|

30x30cm |

1000pcs/ctn |

35x33x15cm |

|

|

60x60cm |

500pcs/ctn |

63x35x15cm | |

|

90x90cm |

250pcs/ctn | 93x35x12cm | |

|

75x75cm |

500pcs/ctn | 77x35x10cm | |

|

40x40cm |

1000pcs/ctn | 42x33x15cm |

Product Description of Medical Crepe Paper

Medical crepe paper is a high-quality, durable, and flexible paper product designed specifically for use in medical environments.It is typically manufactured from 100% medical-grade cellulose fibers, which provide the necessary strength and barrier properties required for medical applications.The paper is usually available in rolls or sheets, and comes in various sizes and colors to meet the diverse needs of healthcare facilities.

The creping process, which involves adding a crinkled texture to the paper, enhances its flexibility and allows it to conform easily to different shapes and surfaces.This process also increases the paper's tensile strength and absorbency, making it suitable for a wide range of medical applications.Medical crepe paper is often used as a wrapping material for sterilization, as it provides an effective barrier against microorganisms and contaminants while maintaining sterility until the point of use.

Product Features of Medical Crepe Paper

Medical crepe paper boasts several key features that contribute to its effectiveness and reliability in medical settings:

1. High Tensile Strength: The creping process enhances the tensile strength of the paper, allowing it to withstand the rigors of sterilization processes such as autoclaving and ethylene oxide (EtO) sterilization without tearing or disintegrating.

2. Flexibility and Conformability: The crinkled texture of crepe paper allows it to easily conform to various shapes and surfaces, making it ideal for wrapping medical instruments, trays, and other items of varying sizes and contours.

3. Barrier Properties: Medical crepe paper provides an effective barrier against microorganisms, dust, and other contaminants, ensuring the sterility of wrapped items until they are ready for use.

4. Breathability: Despite its barrier properties, crepe paper is breathable, allowing steam and gas to penetrate during the sterilization process while preventing the ingress of contaminants afterward.

5. Non-Toxic and Biodegradable: Made from 100% medical-grade cellulose fibers, medical crepe paper is non-toxic and biodegradable, making it a safe and environmentally friendly choice for healthcare settings.

6. Color Coding: Available in various colors, medical crepe paper can be color-coded to differentiate between different types of sterilized items or procedures, enhancing organization and efficiency in medical facilities.

Product Advantages of Medical Crepe Paper

The use of medical crepe paper offers several significant advantages that enhance the efficiency, safety, and hygiene of medical procedures:

1. Enhanced Sterility: Medical crepe paper provides a reliable barrier against microorganisms and contaminants, ensuring that medical instruments and other items remain sterile until they are needed. This helps prevent infections and complications during medical procedures.

2.Versatility: The flexibility and conformability of crepe paper make it suitable for wrapping a wide range of items, from small surgical instruments to larger trays and equipment.Its adaptability ensures that healthcare providers can use it in various scenarios without compromising on protection.

3.Ease of Use: The high tensile strength and durability of crepe paper make it easy to handle and wrap items securely.It can withstand the mechanical stresses of sterilization processes without tearing or compromising the sterility of the contents.

4.Environmental Sustainability: As a biodegradable product made from natural fibers, medical crepe paper offers an environmentally friendly option for healthcare facilities looking to reduce their ecological footprint.

5.Cost-Effective: Medical crepe paper is a cost-effective solution for maintaining sterility in healthcare settings.Its durability and effectiveness reduce the need for frequent replacements, saving both time and resources.

6.Improved Organization: The availability of crepe paper in various colors allows for effective color-coding of sterilized items, enhancing organization and workflow efficiency in medical facilities.

Usage Scenarios of Medical Crepe Paper

Medical crepe paper is used in a variety of medical and healthcare scenarios, each requiring a clean and sterile environment to ensure patient safety and successful outcomes:

1.Surgical Procedures: In operating rooms, medical crepe paper is used to wrap surgical instruments, trays, and other equipment to maintain sterility until they are required during surgery. Its high barrier properties prevent contamination, ensuring a safe surgical environment.

2.Sterilization Departments: In sterilization departments of hospitals and clinics, crepe paper is used to wrap items before autoclaving or EtO sterilization. Its ability to withstand high temperatures and chemicals makes it an ideal choice for these processes.

3.Dental Clinics: Dental practitioners use medical crepe paper to wrap dental instruments and equipment, ensuring they remain sterile until used for patient treatments. The paper's flexibility allows it to conform to various shapes and sizes of dental tools.

4.Outpatient Clinics: In outpatient settings, crepe paper is used to wrap and protect medical instruments and supplies, ensuring sterility during minor procedures and examinations.

5.Emergency Rooms: Emergency rooms require a constant supply of sterile instruments and supplies. Medical crepe paper helps maintain the sterility of these items, ensuring they are ready for immediate use in critical situations.

6.Veterinary Clinics: Veterinary clinics also use medical crepe paper to wrap and sterilize instruments and equipment used in animal surgeries and treatments, ensuring a hygienic environment for veterinary care.

Relevant introduction

Our company is located in Jiangsu Province, China.Super Union/SUGAMA is a professional supplier of medical product development,covering thousand of products in the medical field.We have our own factory that specialized in manufacturing gauze,cotton,non woven products.All kinds of plasters,bandages,tapes and the other medical products.

As a professional manufacturer and supplier of bandages, our products have gained a certain popularity in the Middle East, South America, Africa and other regions. Our customers have a high degree of satisfaction with our products and a high repurchase rate. Our products have been sold to all over the world, such as the United States, Britain, France, Brazil, Morocco and so on.

SUGAMA has been adhering to the principle of good faith management and customer first service philosophy, we will use our products based on the safety of the customers in the first place, so the company has been expanding in a leading position in the medical industry SUMAGA has always attached great importance to innovation at the same time, we have a professional team responsible for developing new products, this is also the company each year to maintain rapid growth trend Employees are positive and positive. The reason is that the company is people-oriented and takes care of every employee, and employees have a strong sense of identity.Finally, the company progresses together with the employees.